Worm Gearboxes

Low-maintenance right-angle gear units for smooth operation and high self-locking capability

Quiet and space-saving for demanding applications

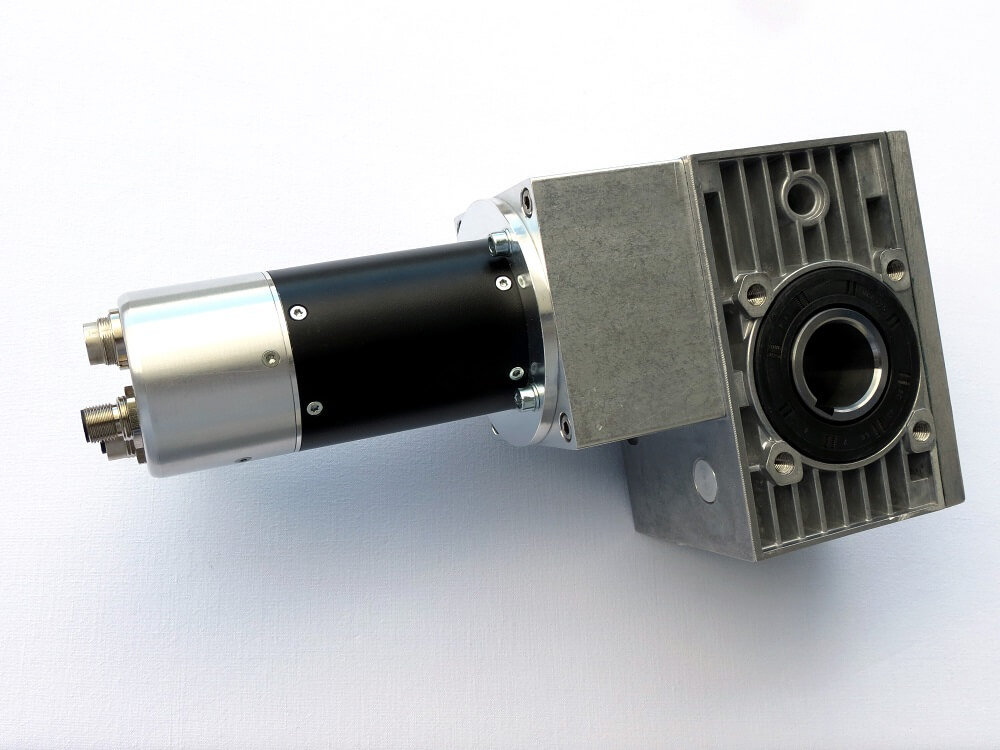

The SWG worm gearboxes from SPAT® are ideal for applications with limited installation space where quiet, powerful torque transmission is required. Their right-angle design allows the motor and output shaft to be integrated in a particularly compact way – perfect for tight machine layouts.

Proven technology for precise motion

Our worm gearboxes stand out with their high self-locking capability, exceptionally smooth operation, and durable construction. They are particularly suitable for positioning tasks where back-driving must be prevented — such as in holding functions or vertical motion systems. The SWG series integrates perfectly with SPAT motors for complete drive solutions.

Your advantages with SPAT® SWG worm gearboxes

holds position even without an additional brake

space-saving integration in tight installations

ideal for noise-sensitive environments

designed for continuous operation

engineering and quality from Saxony

thanks to in-house development and assembly

Typical applications

Our SWG worm gearboxes provide a reliable solution for a wide range of industrial applications – efficient, quiet, and low-maintenance. Let us advise you personally!

FAQ

Worm Gearboxes (SWG)

Answers to frequently asked questions about use, technology, and integration.

Worm gearboxes allow right-angle power transmission and offer a high degree of self-locking — ideal for positioning tasks where back-driving must be avoided.

Yes. SPAT offers various gear ratios and shaft configurations — tailored precisely to your application requirements.

They are extremely low-maintenance thanks to high-quality materials, a sealed design, and long-lasting lubrication.