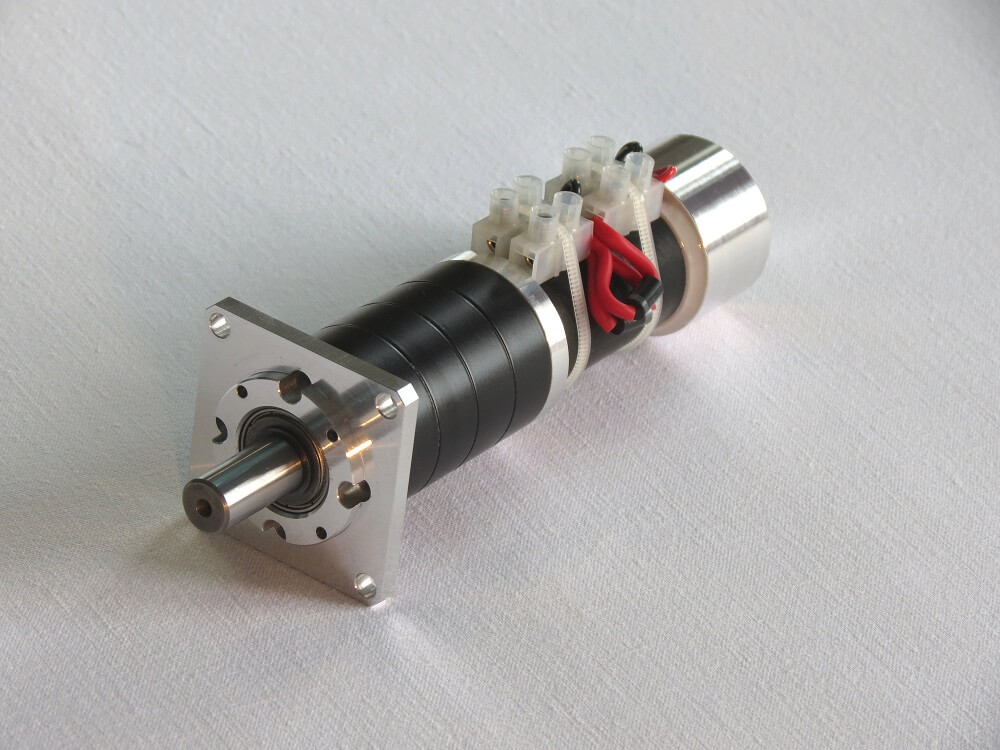

Planetary Gearboxes

Powerful and precise transmission – ideal for tight installation spaces

Maximum torque in minimum space

The SPG planetary gearboxes from SPAT® offer an outstanding balance of torque, size, and smooth operation. With their compact design and high gear ratios, they are perfectly suited for applications requiring precise and reliable power transmission — even where space is limited.

Customizable combinations for modular drive solutions

The SPG series is perfectly matched to our DC and BLDC motors and can be flexibly combined with encoders or control units. These gearboxes feature low torsional backlash, quiet operation, and long service life — ideal for dynamic motion processes with high repeatability.

Your advantages with SPAT® SPG planetary gearboxes

powerful performance in a compact form

reliable even in continuous operation

suitable for sensitive environments

for precise positioning tasks

engineering and quality from Saxony

in-house development and assembly

Typical applications

Our SPG planetary gearboxes can be flexibly integrated and combined with SPAT motors and controllers. We’ll be happy to advise you personally on the optimal solution for your application.

FAQ

Planetary Gearboxes (SPG)

Answers to frequently asked questions about use, technology, and integration.

Our planetary gearboxes are compatible with many DC and BLDC motors from the SPAT product family — depending on the required torque and size.

SPG gearboxes are ideal for positioning tasks, high loads, and compact machine layouts — for example in packaging, robotics, or medical technology.

Yes. The SPG series offers multiple gear stages, which we configure precisely to match your application.