Industry 4.0

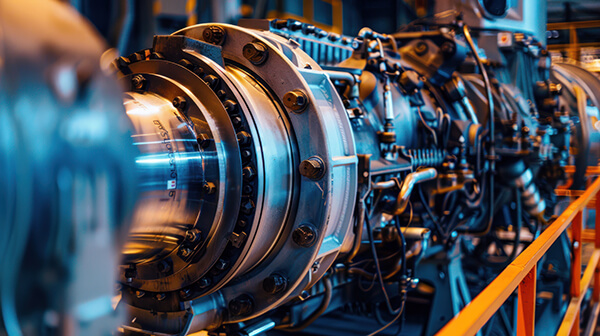

Drive technology as the key to connected, flexible, and efficient production processes

Connected, flexible, smart – what drives modern industry

Industry 4.0 marks a new era of manufacturing: connected, automated, flexible, and data-driven. Drive systems play a central role in this transformation – they form the interface between digital control and physical motion. What’s needed are intelligent, communicative drives that can monitor their condition, regulate themselves adaptively, and integrate seamlessly into heterogeneous control architectures – all with minimal installation effort.

Bus-capable drive solutions with integrated intelligence

SPAT® offers modular, bus-capable drives with integrated control and comprehensive sensor technology. With standardized interfaces (CANopen, EtherCAT, PROFINET, and more), our compact drives can be seamlessly embedded into Industry 4.0 environments. Features such as predictive maintenance, real-time monitoring, and decentralized intelligence make them the ideal solution for modern production systems.

SPAT® technology as a platform for scalable automation

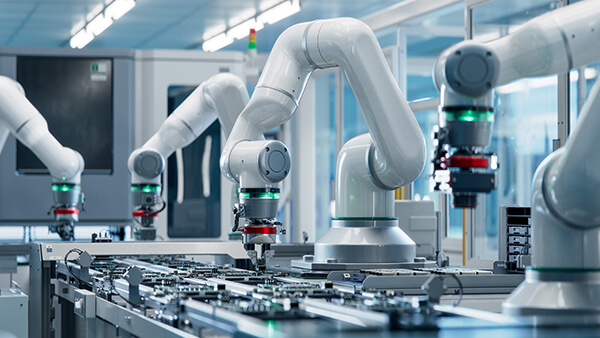

Our drives support decentralized system architectures that are increasingly in demand in Industry 4.0 environments. With an intelligent, space-saving design and easy integration into modular machine concepts, they make a vital contribution to the digitalization of production. Whether for format adjustments, connected assembly systems, or autonomous production lines – SPAT® delivers the drive technology for future-ready manufacturing.

Your advantages with SPAT® compact drives

with high process stability

ideal for tight installation spaces

CANopen, EtherCAT, PROFINET, and more

for customer-specific requirements

with integrated diagnostics and monitoring

robust and powerful, proven in custom drive solutions

Typical applications in the Industry 4.0 context

Planning a connected machine or looking to make your production Industry 4.0-ready? With SPAT®, you benefit from adaptive, intelligent drive technology – engineered for the demands of digital manufacturing.

FAQ

Drive Technology for Industry 4.0

Answers to frequently asked questions about precise and high-performance drive solutions for Industry 4.0 applications.

Yes. Our compact drives feature interfaces such as CANopen, EtherCAT, and PROFINET, allowing seamless integration into modern control architectures.

Absolutely. Our systems require no control cabinet space, include integrated power electronics, and fully support modular, decentralized automation concepts.

Yes. Our drives can be equipped with sensors for condition monitoring and data communication, enabling early detection of maintenance needs and preventing unplanned downtime.