SPAT® Spezialantriebstechnik

Innovative electric drive systems for mechanical and plant engineering

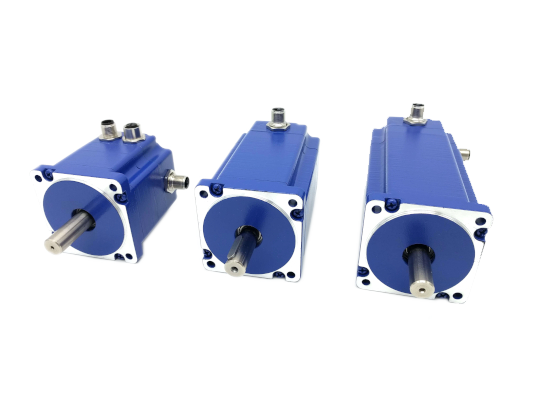

Drive systems from the SPAT MDS platform – individually configured for your application.

Compact, connected drive systems – bus-capable, efficient and ready for Industry 4.0.

Over 30 years of expertise in motion technology – deep technical know-how for complex challenges.

Company

Drive systems – as individual as your application

For more than 35 years, SPAT has been supplying electric drive systems from the heart of Saxony for demanding machines and equipment.

Individuality for us does not start from a blank sheet of paper, but from the smart combination of proven modules in our SPAT MDS platform. This is how we create drive systems that match your application precisely – with standardised interfaces, high precision and efficient integration.

Products

Our solutions for your motion needs

Our portfolio covers a wide range of motion tasks: from precise positioning drives and dynamic continuous-duty drives for speed-related applications to high-torque drive systems. Each solution is configured to match your specific application.

All systems are based on our SPAT MDS platform – a modular toolbox of motors, gear units, controllers and sensor systems. From these proven modules we assemble the drive system that fits your machine – efficient, powerful and ready for the future.

Precise motion in minimal space – compact, powerful, and versatile.

Accurate feedback for maximum process precision.

Brushless power – durable, low-maintenance, and ideal for dynamic applications.

Compact and robust – optimal torque transmission with exceptionally smooth operation.

High torque, maximum efficiency – perfect for demanding drive applications.

Robust and reliable – proven for custom drive solutions.

Applications – Reliable across many industries

Our drives are used wherever precision, reliability, and adaptability are critical.

From the sensitive world of medical technology to the fast-paced environment of machine building – SPAT® solutions prove their value every day across a wide range of industries.

Hygienic, reliable drive solutions for precise movements in production and filling systems – engineered for sensitive environments.

Compact, dynamic drives for high-speed cycles, precise positioning, and flexible formats – perfect for modern packaging lines.

Durable drive systems for saws, milling machines, and conveyor lines – optimized for dusty environments and continuous operation.

Smart compact drives for conveyors, sorters, and automated storage systems – connected, low-maintenance, and efficient.

We’re ready to turn your vision into reality. With our expertise and customized drive technology, we transform your requirements into innovative, high-performance solutions.

Let’s get started – we’ll accompany you from the initial concept to final implementation.

FAQ

Questions & Answers

Got questions about our products or company? Here are the most common answers. If yours isn’t listed, feel free to contact us directly – we’re happy to help.

SPAT is primarily a partner for series projects in mechanical and plant engineering. Our drive systems are used in series machines, platform concepts and recurring projects.

For design-in and validation, we also support you with functional samples and small quantities in order to technically safeguard the later series.

Our drive systems are used in many industries, including food processing, packaging machinery, medical technology, logistics, woodworking and textile machinery, printing machines, applications in renewable energies and Industry 4.0 environments.

What all applications have in common: precise motion, high reliability and often limited installation space.

We do not see ourselves as a simple supplier, but as a partner for your drive technology. That is why we always take an interest in the concrete application – only if we understand loads, environmental conditions and interfaces can we offer the drive system that really fits.

Instead of standard single components, we provide compact, intelligent drive systems based on our SPAT MDS platform. Motor, gearbox, controller and sensor system come from a modular toolbox and are matched to each other.

Another important aspect is long-term availability: many of our customers still receive drives today that were introduced 15–20 years ago. If individual components are no longer available, we create a redesign that remains mechanically, electrically and functionally 1:1 compatible. This ensures that your machines can be operated reliably in the long run.

With more than 30 years of experience and in-house development and assembly in Hartha, we offer technical depth, short decision paths and high investment security.

Every project starts with your application: together we clarify loads, environmental conditions, interfaces and requirements regarding function and lifetime. Only when we understand the task can we propose the right drive system.

On this basis, we select suitable modules from the SPAT MDS platform and configure a customer-specific drive system – including sample phase and testing in your machine.

After successful validation, we support you in series supply and act as a partner for adaptations, variants, redesigns and retrofit projects.

Yes. Our compact drives are bus-capable and can be integrated via common interfaces such as CANopen, EtherCAT, Profinet and other systems.

Thanks to integrated electronics and sensor systems, condition data, diagnostics and process information can be made available – ideal for modern, digital production environments and Industry 4.0 concepts.

We generally design our drive systems for long-term availability and accompany many series over many years or even decades.

If components of an existing drive system are discontinued, we develop a redesign that remains mechanically, electrically and functionally compatible. This allows your machines to continue operating without any need to change your mechanical design.