Electrification of hydraulic cylinders

From hydraulic cylinder to intelligent electric cylinder

Hydraulic cylinders in industrial trucks and agricultural machinery

With the ongoing electrification of drivetrains, the question of alternatives to widely used hydraulic actuation systems is being asked more and more often.

SPAT® offers compact, high-performance drives for electric cylinders that are specifically optimised for on-board power systems (12 / 24 / 48 V) in battery-powered vehicles. This enables clean, efficient and intelligently controllable cylinder systems that can replace hydraulic cylinders in many applications.

Hydraulics in mobile use: proven – but with side effects

Environmental aspects

Hydraulic cylinders offer high power density and have been the standard in mobile machinery for decades. In practice, however, typical drawbacks become apparent which are increasingly critical in modern applications. Leakage and contamination are among the most visible issues: oil losses lead to soiled machines, workshop floors and outdoor areas – particularly problematic in logistics centres, food environments and agriculture.

Energy balance

From an energy perspective, conventional hydraulic drives are also at a disadvantage. Throttling losses in valves, line resistance and internal leakage cause part of the input energy to be dissipated as heat in the oil. Especially in battery-powered vehicles, this means valuable range is lost – a factor that is increasingly in focus in electric or hybrid concepts.

MAINTENANCE

On top of this comes the maintenance effort: oil changes, filters, hoses, seals and bleeding are part of the standard programme, supplemented by faults caused by contaminated or overheated oil. This ties up maintenance resources and increases the risk of unplanned downtime. In parallel, system complexity grows: in addition to the cylinder itself, a power unit, tank, valve blocks, lines and cooling are required. All of this costs space and weight and increases the design and organisational effort in the vehicle.

SOLUTION

Wherever high forces, long strokes and extremely compact installation conditions do not necessarily require hydraulics, it is worth considering an electric alternative.

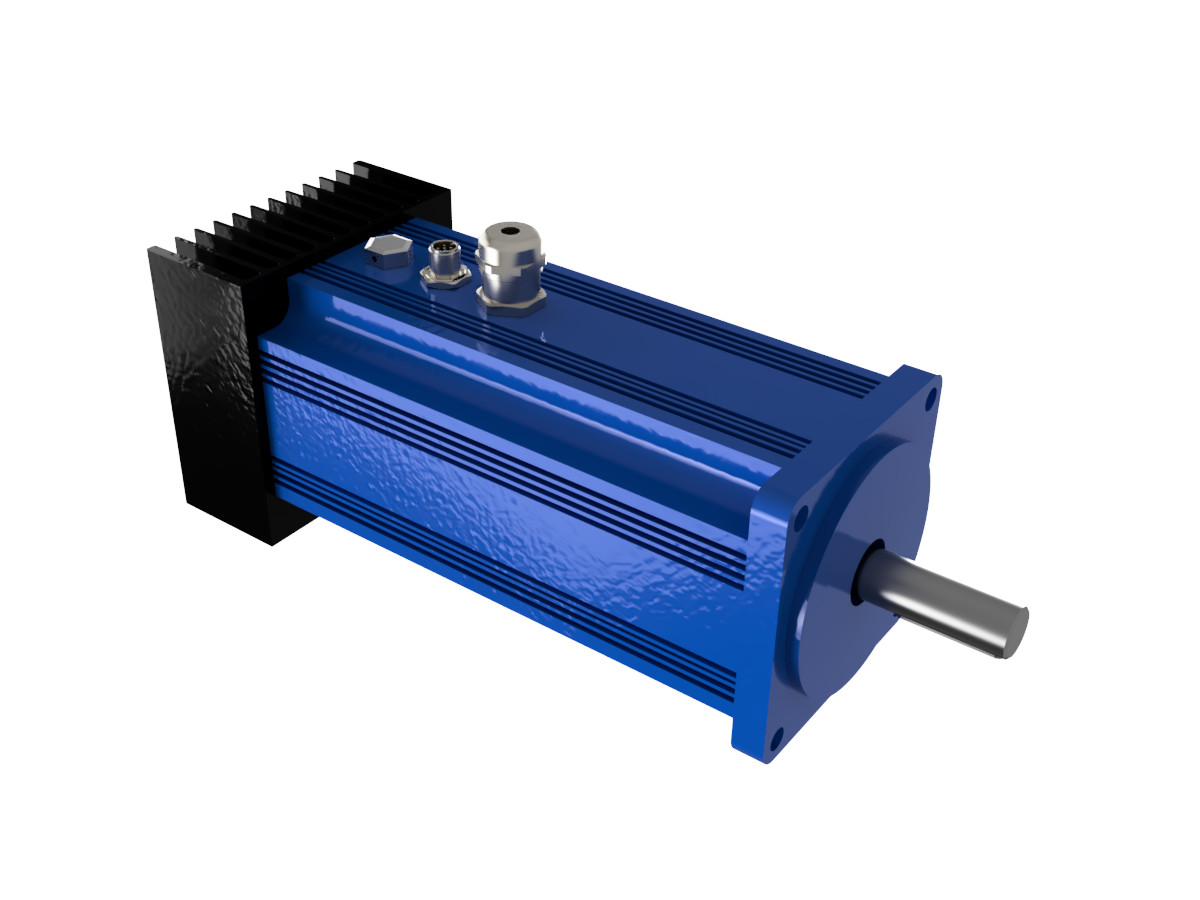

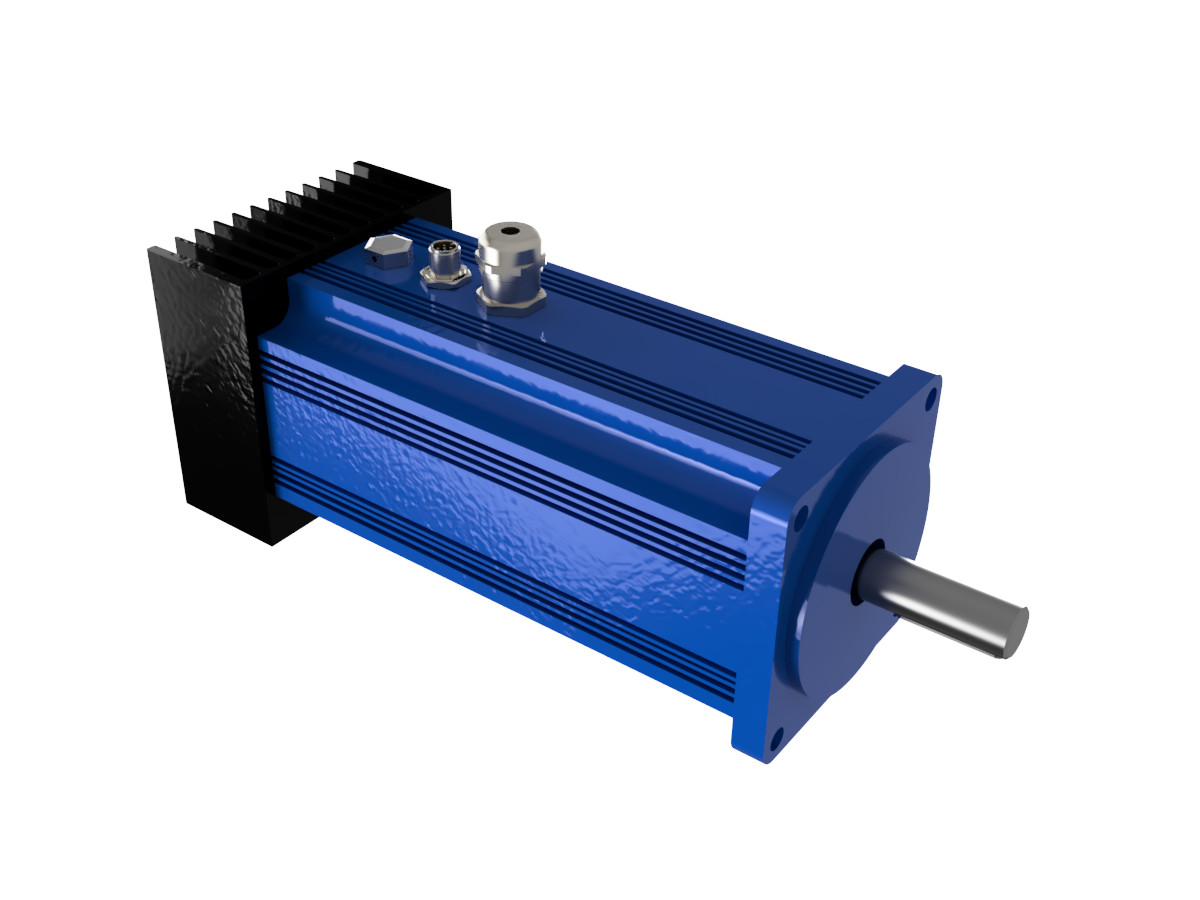

Electric cylinders with integrated SPAT® drives

Electromechanics

Instead of oil, valves, and hoses, electromechanical cylinders use ball or roller screw drives, electric motors, and electronics. SPAT® supplies compact drives with high power density that can be mounted directly on the cylinder.

Drive concept

Our drive concepts for electric cylinders are based on the SPAT MDS platform and are specifically designed for use in mobile on-board power systems. Depending on the vehicle and battery system, they support 12, 24 or 48 V DC and cover an output range of up to around 5 kW – sufficient for demanding lifting and positioning functions in industrial trucks, aerial work platforms or agricultural machinery.

Drive System

Motor, absolute encoder, drive electronics and holding brake are integrated into a compact, decentralised drive system. Via bus-capable interfaces such as CANopen, the drives can be connected directly to the vehicle controller and fully integrated into the control architecture. Parameterisable profiles for position, speed and force make it possible to adapt the electric cylinder precisely to the respective task. The cylinder thus becomes an intelligent mechatronic module that operates without a separate hydraulic infrastructure and can be controlled in the vehicle like any other electric axis.

Recover energy instead of heating oil – recuperation during lowering

Energy loss

Especially in lifting applications in industrial trucks or on attachments of agricultural machines, lowering the load generates usable energy. In hydraulic systems, this energy is usually “destroyed” in throttling valves and oil heating.

Efficiency improvement

With an electrically driven cylinder, the situation is fundamentally different. When lowering, the motor operates in generator mode and recovers part of the energy that was previously used for the lifting movement. This energy flows back into the DC link or directly into the battery and is then available for further driving or lifting operations. Depending on the load profile and number of cycles, this can significantly increase the overall efficiency of the vehicle. For battery-electric industrial trucks and compact agricultural machines, this means more range, fewer charging cycles and a noticeably better CO₂ footprint for the overall system.

Your benefits with SPAT® compact drives for electric cylinders

Clean operation without hydraulic oil – ideal for logistics, food environments and agricultural land.

Lower losses than in hydraulic throttling sections, plus recuperation during lowering.

Motor, electronics, absolute encoder and holding brake mounted directly on the cylinder – minimal cabling and control cabinet effort.

Accurate positioning and speed profiles, independent of oil temperature, viscosity and valve characteristics.

Designed for 12 / 24 / 48 V DC, bus-capable and compatible with modern vehicle controllers.

No oil changes, no filters – instead, condition monitoring via current, temperature, cycle counts and status information.

Typical application areas for electric cylinder systems

Industrial trucks

Agricultural machinery

You want to replace hydraulic cylinders with electric cylinders or implement new functions directly electrically? With SPAT® drive systems for electric cylinders, you can draw on a proven modular platform: compact drive units with integrated electronics, absolute encoder and holding brake, designed for 12 / 24 / 48 V in mobile applications.

Based on this platform, we configure a solution together with you that matches your cylinder mechanically and fits your on-board power system and controller electrically – including positioning function, brake control and bus interface.

FAQ

Drive technology for electric cylinders

Answers to frequently asked questions about the electrification of hydraulic cylinders

In many cases where medium forces, limited strokes and high cycle counts occur – for example for lifting, tilting and adjustment functions in industrial trucks, as well as flap, dosing and adjustment tasks in agricultural machinery. For extremely highly loaded main working cylinders with very high power density, hydraulics can still be the better choice.

Electrified cylinder systems reduce losses, enable recuperation during lowering and work without a hydraulic power unit. This increases range and reduces energy costs. At the same time, the effort for oil, filters and leakage clean-up is eliminated.

Many solutions on the market consist of a motor plus external drive electronics that primarily control speed. Topics such as position control, end-position detection, brake control and feedback then have to be solved with additional components (limit switches, sensors, relays, external controllers) and integrated into the control system with considerable effort.

Our drives for electric cylinders follow a different approach:

Plug-and-play system instead of individual components

Motor, power electronics, absolute encoder and holding brake are integrated into a compact, decentralised drive system.True positioning function in the drive

The drive can control position, speed and motion profiles itself – end positions and intermediate positions are stored in the drive, not laboriously mapped in the PLC.Integrated brake control and feedback

Control of the holding brake and monitoring of relevant parameters (current, temperature, status) are already included in the system.Less cabling, less control effort

Instead of many individual cables to sensors, limit switches and brake relays, you ideally only need power and bus – the rest is encapsulated in the drive unit.

This turns motor plus cylinder into a complete, intelligent axis module that is significantly easier to integrate than classic motor-inverter combinations.

Depending on the version, the drives can be integrated via digital I/Os or via fieldbus (e.g. CANopen). The controller has access to position, speed, currents, temperatures and diagnostic information. This makes it easy to implement motion profiles, safety functions and service concepts.

Yes. In many projects, individual functions – such as auxiliary cylinders or flaps – are initially converted from hydraulics to electric cylinders, while central hydraulic functions remain in place for the time being. This allows electrification to be implemented step by step and with manageable risk.

Since there is no oil, no filters and no hoses, maintenance effort is significantly reduced. At the same time, the risk of leaks and the associated cleaning costs decrease. Overall, switching to electrified cylinder systems can noticeably reduce the total cost of ownership (TCO) over the lifetime of the machine.