DC Industry

DC drive technology for mobile, decentralised and energy-efficient applications

DC industry – DC grids for the factory of the future

Traditionally, factories are supplied from the 400 V three-phase AC grid. On closer inspection, however, many consumers internally operate with DC voltage, which is provided by power supplies, transformers or converters. In the factory of the future, a significant share of energy distribution will therefore take place via DC grids.

Instead of connecting every machine, every subassembly and every charging point via its own 400 V AC supply and converter, a common DC bus supplies drives, machine modules, process equipment, building infrastructure, storage systems, charging points and renewable generators within a consistent energy network.

Fewer conversion stages, better utilisation of energy and flexible coupling of PV systems, battery storage and e-mobility make DC industry a key element for energy-efficient production – and an important foundation for concepts such as the All Electric Society, in which industry, buildings and mobility are electrically powered and interconnected across sectors.

SPAT® develops and manufactures compact drive systems that can be operated directly from the industrial DC grid (650 V DC) – based on our SPAT MDS Platform. This allows us to bring the benefits of DC industry right down to small drives from frame size 60 mm. As an active member of the ODCA (Open DC Alliance), we help shape the further development of DC grids in industry and drive the practical transition from classic AC supplies to future-proof DC architectures.

DC grids – fewer losses, less power, lower CO₂

In conventional plants, each axis is supplied by its own drive inverter with rectifier, DC link and inverter stage – and the energy generated during braking is often converted into heat in brake resistors.

In the DC industry grid, energy is converted to DC and distributed via a common bus. This reduces conversion losses, enables the use of braking energy within the grid and simplifies the integration of storage systems and renewable generators.

In detail, among others, the following advantages arise:

Only one conversion stage from the public grid to the DC bus – reducing conversion losses. In pilot plants, this has enabled up to 10% energy savings in the drive section, and even up to 20% in individual applications.

Regenerative braking instead of brake resistors: braking energy from dynamic axes is fed back into the DC bus and used by other consumers or stored in batteries – instead of being dissipated as heat.

By using storage systems and the common DC grid, the imported grid power can be significantly reduced; in demonstration plants, feed-in peaks have been reduced by up to 80%, and the required connection power of sub-systems by up to 85%.

PV systems and battery storage in any case operate on DC and can be integrated into DC grids with fewer conversion stages and lower losses.

The result is lower energy costs, reduced current draw at the grid connection point and a measurable contribution to reducing the CO₂ footprint of production.

SPAT drive systems directly on the DC bus – down to low power ranges

Our drives internally already work with DC links. With the SMC motor controllers of the HV series, we realise drive systems that are supplied directly from the DC industry grid (e.g. 650 V DC) – without the detour via separate power supplies and AC inverters. This allows these drives to actively participate in energy sharing in the DC grid and increase the overall energy efficiency of the plant.

DC industry at SPAT is not limited to large servo drives: we bring this technology down to compact, decentralised drives from frame size 60 mm.

Your benefits with SPAT® drive systems for DC industry

Designed for industrial DC grids with a nominal voltage of 650 V DC

Fewer conversion stages, use of braking energy and reduced feed-in peaks

Drive systems from frame size 60 mm

Only two live conductors – less copper, lower line losses and reduced installation effort

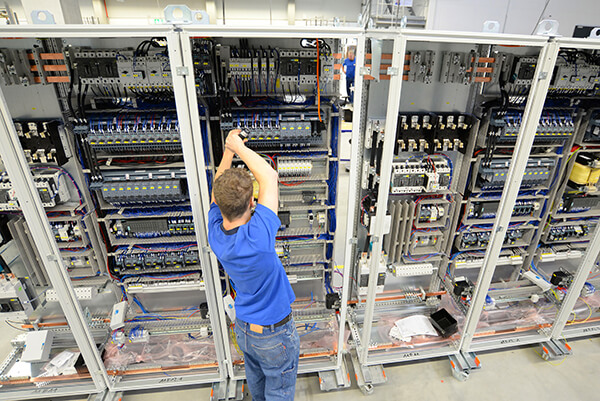

Less control cabinet space, short cable runs and high flexibility for modular machine concepts

Motor, gearbox, controller and encoder precisely matched – ready for PV and storage integration and energy-flexible factory concepts

Typical application areas for DC industry drive systems

Wherever many electric drives, power converters, storage systems and renewable sources come together and energy efficiency, grid charges and CO₂ footprint are key factors. We will be happy to analyse your plant with you and identify where a DC industry concept – from a first pilot cell to a fully DC-based factory – makes technical and economic sense.

FAQ

Drive Technology in DC Applications

Answers to frequently asked questions about precise, high-performance drive solutions for DC systems.

Our drive systems can be designed for industrial DC grids in the range of 650 V DC, as defined in DC industry concepts. On the motor side we work with adapted DC links and matching SMC motor controllers. For higher DC voltage levels, project-specific adaptations are possible.

DC industry is not limited to greenfield projects. In many cases, existing production lines can be gradually connected to a DC grid via DC sectors or individual machine modules. We support both new installations and retrofit concepts, where selected drive groups are converted to DC operation step by step.

No. A transition to DC industry does not necessarily mean that all existing AC drives must be replaced at once. In practice, hybrid structures are common, where existing AC technology continues to operate and new or modernised drives are supplied directly from the DC bus. Together with you, we develop a migration concept that fits your installed base and investment framework.

By reducing the number of conversion stages, using braking energy within the DC grid and improving the integration of storage systems and photovoltaics, both energy consumption and imported grid power can be significantly reduced. In drive-intensive plants, this can lead to noticeably lower energy costs, reduced feed-in peaks and corresponding savings in grid connection capacity and peak-load charges.

On the DC distribution level, only two live conductors (L+ and L−) plus protective earth are required. Compared to three-phase AC systems, this allows copper usage, cable cross-sections and line losses to be significantly reduced. This not only lowers material and installation effort, but also the CO₂ footprint of the electrical infrastructure – especially over long cable runs in large production facilities.

Yes. A major advantage of our approach is that we can implement DC-capable drive systems down to motor diameters from 57 mm. This means that smaller axes, handling systems, auxiliary drives and secondary consumers can also be integrated into the DC grid, instead of operating as isolated AC islands with their own inverter. Especially in plants with many small drives, the efficiency potential adds up significantly.

SPAT® is an active member of the ODCA (Open DC Alliance) and contributes to the further development of DC industry grids at association level. We feed in our experience from real drive projects and ensure that our solutions are aligned with current guidelines, interface concepts and protection concepts. This benefits machine and plant builders who want to adopt DC industry early while relying on future-proof, standard-oriented solutions.

Together with you, we analyse the plant structure, load profiles and regeneration potential and derive a suitable drive concept for the DC grid. This includes the selection of appropriate motor–gearbox combinations, the design of SMC motor controllers for DC operation, as well as the consideration of cabling, protection concept and integration into the higher-level control system. If required, we work closely with your panel builders, plant engineers and energy planners.